vickers hardness test mild steel|what is vickers hardness test : exporters Due to its scaling, the Vickers hardness test is ideal for testing hard materials like steel as well as softer materials like plastic. All in all, the Vickers test has one of the widest hardness ranges among the 4 test . WEB3 dias atrás · Bubbles Bet is a fun and rewarding online casino that offers you a daily free wheel spin, bubblicious promotions, and a thrilling island journey. Join now and enjoy the best games and prizes at Bubbles Bet.

{plog:ftitle_list}

Resultado da In the most likely scenario, a small group of short people split off from nonpygmy populations between 50,000 and 90,000 years ago. The founding group of pygmy ancestors was fairly cohesive, with tribes interbreeding until 2800 years ago. At that point, taller Bantu-speaking farmers probably .

The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .The Vickers hardness test is a versatile hardness test method, used for both macro and micro hardness testing. It has a broad load range, and is suitable for a wide range of applications and materials.The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of h.Vickers Hardness Testing Formulas, Calculator and Review. The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid .

Due to its scaling, the Vickers hardness test is ideal for testing hard materials like steel as well as softer materials like plastic. All in all, the Vickers test has one of the widest hardness ranges among the 4 test .

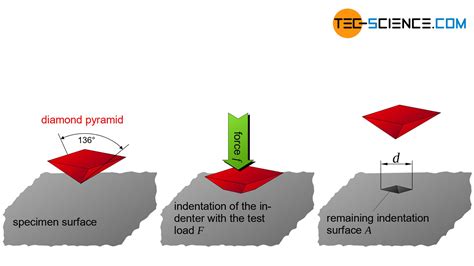

The Vickers hardness test is a method of measuring the hardness of a material by indenting it with a diamond indenter in the shape of a right pyramid with a square base and an angle of .

Hardness Testing of Metals: Rockwell, Brinell, Vickers, Knoop, and Leeb Tests. This article provides an overview of common hardness testing methods for metals, comparing .

The Vickers hardness test or the 136 degree diamond pyramid hardness test is a microindentation method. The indenter produces a square indentation, the diagonals of which .Depending on the magnitude of the test force according to ISO standard (and hence on the Vickers Method, e.g.: HV 0.01; HV 1; HV 10), the Vickers process can be subdivided into three .

The Vickers method has a test load range from 1 gf according to ISO respectively from 1 gf up to 120 kgf according to ASTM, which means that this method can be used for hardness testing across all load ranges (from the micro to the low .15.2.3.2 Hardness Test. A Vickers hardness testing machine was employed to determine the hardness differences of all the rolled strip specimens in the thicker, thinner, and transition zones by applying a load of 1 N with a dwelling time of 12 s. Hardness measurements were performed on the cross-section surfaces of the rolled strips along the .

The Vickers hardness test method, also referred to as a microhardness test method, is mostly used for small parts, thin sections, or case depth work. The Microhardness test procedure, ASTM E-384, specifies a range of light loads .

The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface. . For hard materials like steel, Rockwell hardness can be used. Comparison . Brinell hardness. The Brinell hardness scale is a widely accepted measure of hardness in materials. It involves pressing a ball of steel (or tungsten carbide for harder materials) into the test piece at a constant and known force. The softer the material, the deeper the ball will penetrate and vice versa. The next step is to take a measurement of the diameter .To increase the hardness of the steel alloy. Mild steels (1045, A36) Alloy steels (4140, 4240) Tool steels (D2, A2, O1) . suitable for a wide range of materials, including metals, ceramics, and plastics. Due to its small indentation size the Vickers hardness test allows for testing on very thin materials and provides accurate results. Where:

VICKERS HARDNESS TEST Aim: To determine the Vickers hardness of hard materials such as hardened steel and moderately hard materials such as brass, copper and aluminium. Theory: It is similar in principle to Rockwell hardness test, but utilizes a different indentor and different magnitudes of loads. Hardness testing is an essential test in the metal manufacturing industry, and Vickers hardness is one of the most widely used hardness measurements today. The computer-assisted Vickers hardness test requires manually generating indentations for measurement, but the process is tedious and the measured results may depend on the operator’s experience. In . The features of non-destructive testing of steel pipes with a long service life in terms of dynamic hardness parameters are considered. The limited applicability of normal and lognormal .

The average hardness value for the mild steel being tested is 163 HV and 168 HV, the highest hardness value is 174 HV and the lowest hardness value is 156 HV, so that a tolerance of ± 10 HV commonly used in the Vickers test is sufficient. Keywords: Hardness, ST 60 Steel , Loading Variations, Vicker s Test Mild steel, copper alloy, aluminum alloy, malleable cast iron: HRC: Diamond cone: 1471: 20-70: . Note: 1. The Vickers hardness test can use a test force greater than 980.7N;2. The micro Vickers test force is recommended. Characteristics and Application of Vickers Hardness (1) The geometrical shape of the indentation is always similar, while . Mild steel: 130: 1,500 kgf: Medium-hard metals (general) 80 – 300: 1,500 kgf: Soft brass: 60: 500 kgf: Soft metals (general) 26 – 100: . Vickers Hardness Test. The Vickers hardness test is a versatile and precise method suitable for a wide range of materials, from soft metals to hard ceramics, and is especially valuable for micro hardness . The advantages of the Vickers hardness test is the extremely accurate readings can be taken and just one type of indenter is used for all types of metals. The Vickers test is capable of testing soft and hard material. The disadvantage of this method is it takes time because the indentation must be measured under the microscope. Besides, the sample must .

To determine the indentation hardness of mild steel, brass, aluminium etc. using Vickers hardness testing machine. Apparatus used : Vickers hardness testing machine. the time. The load is applied for a period of 10 to 15 seconds. Indentation diagonal length. Indentation diagonal length. hv=0.8191F/d 2: d1 .Mild steel has a relatively low tensile strength, but it is cheap and easy to form; surface hardness can be increased through carburizing. . The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The . The equivalent hardness of a steel sample of 300 BHN in the Vickers scale is 303 HV. To perform this conversion, refer to a steel harness conversion chart and follow these steps: Look up the Brinell hardness, 300 . HRC: Uses a 150kg load and a diamond cone indenter, suitable for very hard materials like quenched steel. 3. Vickers Hardness (HV) Vickers hardness is determined by pressing a diamond square cone with a 136° top .

Due to its scaling, the Vickers hardness test is ideal for testing hard materials like steel as well as softer materials like plastic. All in all, the Vickers test has one of the widest hardness ranges among the 4 test .The Brinell hardness test of metals and alloys. . Brinell Hardness Number; Soft brass: 60: Mild steel: 130: Annealed chissel steel: 235: White cast iron: 415: Nitrided surface: 750: Steel Hardness versus Strength. Steel Hardness versus Strength; Brinell Vickers Rockwell Equivalent Rm; Impression Diameter (mm) Hardness HB. Hardness HV .

sorts of steel components. The Phase II 900-398 is our macro-Vickers hardness tester, covering the load range from 1kg to 50kg, with digital technology. Using guidelines for ASTM E-384/92 Vickers hardness testers . The advantages of the Vickers hardness test are that extremely accurate readings can be taken, and just one type of indenter is .

the hardness value is calculated based on the applied load and the indentation size. Vickers belongs to the optical methods. Vickers Hardness The Knoop hardness test is similar to the Vickers test but uses a rhombic-based diamond indenter instead of a pyr-amid. It is commonly used for measuring the hardness of thinVickers Hardness Testing Formulas, Calculator and Review . The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number ( HV ) or Diamond Pyramid Hardness ( DPH ). The hardness number can be converted into units of pascals , but .Hardness test according to Vickers. On metallic materials from very low to very high hardness, the Vickers hardness test is applicable. . The hardness test according to Brinell is for metallic materials with the steel ball is determined as indenter only up to 450HB, the overlying hardness values were determined with the hard metal ball.In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested.

ABOUT STEEL HARDNESS CONVERSION CALCULATOR. Steel hardness is a critical parameter that directly influences a material's performance in various applications. Different scales, such as Rockwell C (HRC), Brinell (HB), Vickers (HV), and Rockwell B (HRB), are employed to quantify the hardness of steel and other metals.Hardness test methods. Common tests for hardness in metals involve measuring the resistance to indentation by a hardened steel or diamond ball, cone or pyramid. The common test methods include: – Brinell. Vickers. Rockwell. The hardness figures do not have units.Mild steel: 120 HB 18–8 (304) stainless steel annealed: 200 HB [3] Quenched and tempered steel wear plate: 400-700 HB Hardened tool steel: 600–900 HB (HBW 10/3000) Glass: . Vickers hardness test; References Tabor, David (2000). The Hardness of Metals. Oxford University Press. .

The Vickers hardness test is similar to the Brinell test. However, it uses a four-sided inverted diamond pyramid with an apex angle of 136°. The Vickers hardness number (HV) is the ratio of the impressed load to the square indented area. The Vickers hardness test is of particular value for hard, thin materials where hardness at a spot is required.

refractometer calf serum protein

Resultado da 25 de set. de 2021 · Escalação. Arbitragem. Na volta da torcida, Tubarão vence o Vitória no Café. A equipe principal do Londrina Esporte Clube .

vickers hardness test mild steel|what is vickers hardness test